This presets the counter to 1 (ie, 001) and so PE goes low again. The counter then increments in the normal manner until it reaches "7" again. Counter IC3 operates in the same manner except that the clock signal is derived from IC2s O3 output. The counter outputs (O1, O2 & O3) drive NPN transistors Q1-Q6 and these in turn drive the LEDs (ie, the LEDs indicate the states of the counters). Normally, the counters are incrementing continuously and the LEDs all appear to be lit. However, when push-button switch S1 is pressed, pin 6 of IC1c goes low and pin 9 of IC1d pulls the Ci input of IC2 high, thus stopping the counters. Finally, toggle switch S2 allows the user to choose between having two dice operating simultaneously or just one.

Monday, September 30, 2013

Low Cost Dual Digital Dice

This presets the counter to 1 (ie, 001) and so PE goes low again. The counter then increments in the normal manner until it reaches "7" again. Counter IC3 operates in the same manner except that the clock signal is derived from IC2s O3 output. The counter outputs (O1, O2 & O3) drive NPN transistors Q1-Q6 and these in turn drive the LEDs (ie, the LEDs indicate the states of the counters). Normally, the counters are incrementing continuously and the LEDs all appear to be lit. However, when push-button switch S1 is pressed, pin 6 of IC1c goes low and pin 9 of IC1d pulls the Ci input of IC2 high, thus stopping the counters. Finally, toggle switch S2 allows the user to choose between having two dice operating simultaneously or just one.

FM Telephone Bug Circuit

Here is a simple transmitter that when connected to a phone line, will transmit anything on that line (execpt the dial tone) to any FM radio. The frequency can be tuned from 88 to about 94Mhz and the range is about 200 feet. It is extremely easy to build and is therefore a good, useful beginner project.

Circuit diagram:

FM Telephone Bug Circuit diagram

FM Telephone Bug Circuit diagram

Parts

R1 180 Ohm 1/4 W Resistor

R2 12K 1/4 W Resistor

C1 330pF Capacitor

C2 12pF Capacitor

C3 471pF Capacitor

C4 22pF Capacitor

Q1 2SA933 Transistor

D1, D2, D3, D4 1SS119 Silicon Diode

D5 Red LED

S1 SPDT Switch

L1 Tuning Coil

MISC Wire, Circuit Board

Notes

1. L1 is 7 turns of 22 AWG wire wound on a 9/64 drill bit. You may need to experiment with the number of turns.

2. By stretching and compressing the coils of L1, you can change the frequency of the transmitter. The min frequency is about 88 Mhz, while the max frequency is around 94 Mhz.

3. The green wire from the phone line goes to IN1. The red wire from the phone line goes to IN2. The green wire from OUT1 goes to the phone(s), as well as the red wire from OUT2.

4. The antenna is a piece of thin (22 AWG) wire about 5 inches long.

5. All capacitors are rated for 250V or greater.

6. The transmitter is powered by the phone line and is on only when the phone is in use. S1 can be used to turn the transmitter off if it is not needed.

7. If you have problems with the LED burning out, then add a 300 ohm 1/4W resistor in series with it.

Source : electronic

RGB To Color Difference Converter Circuit

The circuit diagram shows two LT1398’s from Linear Technology used to create buffered color-difference signals from RGB (red-green-blue) inputs. In this application, the R input arrives via 75Ω coax. It is routed to the non-inverting input of amplifier IC1a and to 1.07-kΩ resistor, R8. There is also an 80.6-Ω termination resistor R11, which yields a 75-Ω input impedance at the R input when considered in parallel with R8. R8 connects to the inverting input of a second LT1398 amplifier (IC1b), which also sums the weighted G and B inputs to create a –0.5Y output.

Yet another LT1398 amplifier, IC2a, then takes the –0.5Y output and amplifies it by a gain of –2, resulting in the +Y output. Amplifier IC1a is configured for a non-inverting gain of 2 with the bottom of the gain resistor R2 tied to the Y output. The output IC1a thus results in the color-difference output R–Y. The B input is similar to the R input. Here, R13 when considered in parallel with R10 yields a 75-Ω input impedance. R10 also connects to the inverting input of amplifier IC1b, adding the B contribution to the Y signal as discussed above.

Amplifier IC2b is configured to supply a non-inverting gain of 2 with the bottom of the gain resistor R4 tied to the Y output. The output of IC2b thus results in the color-difference output B–Y. The G input also arrives via 75-Ω coax and adds its contribution to the Y signal via resistor R9, which is tied to the inverting input of amplifier IC1b. Here, R12 and R9 provide the 75Ω termination impedance. Using superposition, it is straightforward to determine the output of IC1b. Although inverted, it sums the R, G and B signals to the standard proportions of 0.3R, 0.59G and 0.11B that are used to create the Y signal. Amplifier IC2a then inverts and amplifies the signal by 2, resulting in the Y output. The converter draws a current of about 30mA from a symmetrical 5-volt supply.

High Current Low Dropout Voltage Regulator

You can then "trim" to the required output voltage by installing a resistor in series with ZD1. Q2s base-emitter voltage and the 680W base resistor set the current through ZD1 to 0.5mA. This means that the output voltage will be boosted by 0.1V for each 200O of resistance in series with ZD1. Zener diode ZD2 ensures that Q4s maximum rated gate-source voltage is not exceeded. Mosfet Q1 provides reverse polarity protection. Note that Q4 requires a heatsink since it will dissipate about 10W under worst-case conditions. No heatsink is required for Q1. At 3.3A, the regulator reduces the output voltage by just 0.2V. This can be further reduced by paralleling Q1 & Q4 with additional Mosfets.

Sunday, September 29, 2013

Economical Transistor Radio

The specifications, very briefly stated, are:

- medium-wave receiver with ferrite aerial

- optional supplementary aerial

- power supply 1.5 V/10 mA

- 4 transistors

- loudspeaker output

Reservoir Pump Controller

The output (pin 7) therefore swings high, biasing Q1 into conduction. This in turn causes Q4 to conduct, switching on the relay and starting the pump. In addition, when Q4 switches on it supplies base current to Q3 via a 6.8kO resistor. Initially, this current flows through the 47µF capacitor, but once its base-emitter voltage reaches about 0.6V, Q3 conducts. This action latches Q4 in the "on" state, as its base current can flow to ground via Q3 when Q1 stops conducting – which will occur when the rising water level reaches the low probe. When the water level reaches the high probe, the voltage on the non-inverting input (pin 2) of IC1a decreases markedly due to the conductivity of the water.

If trimpot VR1 is correctly adjusted, the output (pin 1) swings high, switching on Q2. This discharges the 47µF capacitor and robs Q3 of its base current, switching this transistor off. This in turn switches off Q4 and the relay. The zener diodes and 1kO series resistors at the probe inputs protect the op amp’s high impedance inputs from the effects of static discharge. The 47µF capacitor in parallel with the base-emitter junction of Q1 prevents the latching function from being activated when power is applied to the circuit. The author’s setup is powered from an old car battery charged from a 12V solar panel.

If trimpot VR1 is correctly adjusted, the output (pin 1) swings high, switching on Q2. This discharges the 47µF capacitor and robs Q3 of its base current, switching this transistor off. This in turn switches off Q4 and the relay. The zener diodes and 1kO series resistors at the probe inputs protect the op amp’s high impedance inputs from the effects of static discharge. The 47µF capacitor in parallel with the base-emitter junction of Q1 prevents the latching function from being activated when power is applied to the circuit. The author’s setup is powered from an old car battery charged from a 12V solar panel.Fast Voltage Driven Current Source

Saturday, September 28, 2013

Computer Off Switch Circuit

Acura Integra EMS P N 30 1060 Installation Instructions

The EMS is a “stand-alone”, which completely replaces the factory ECU and features unique plug and play technology. There is no need to modify the factory wiring harness and in most cases the vehicle may be returned to stock in a matter of minutes. The AEMPro software is configured to work with the factory sensors and equipment, so there is no need for expensive or hard to find sensors, making replacements and repairs as simple as with any stock vehicle. For stock and slightly modified vehicles, the AEMPro software can be programmed with base parameters, providing a solid starting point for beginner tuning. For more heavily modified cars, the EMS has many spare inputs and outputs allowing the elimination of add-on rev-limiters, boost controllers, nitrous controllers, fuel computers, etc.

While the base map may be a good starting point and will save considerable time and money, it will not replace the need to tune the specific application. AEM start-up maps are tuned conservatively and are not intended to be driven aggressively. Ignoring this can and will damage your engine.

If the 30-1060U EMS was purchased, the stock O2 #1 sensor will not be used and should be replaced with the supplied AEM sensor. The 30-1060U furnishes the user with real time, accurate and repeatable air/fuel ratios. The system consists of an internal air fuel ratio (AFR) controller, wiring harness, wide band oxygen sensor and a sensor bung.

Download Acura Integra EMS P/N 30-1060 Installation Instructions

Temperature Sensitive Switch For Solar Collector

This circuit can be used to turn the pump on and off when a solar collector is used to heat a swimming pool, for example. This way the water in the collector has a chance to warm up significantly before it is pumped to the swimming pool. A bonus is that the pump doesn’t need to be on continuously. The basis of operation is as follows. When the temperature of the water in the solar collector is at least 10 °C higher than that of the swimming pool, the pump starts up. The warm water will then be pumped to the swimming pool and the temperature difference will drop rapidly. This is because fresh, cool water from the swimming pool enters the collector. Once the difference is less than 3 °C the pump is turned off again. R10/R1 and R9/R2 each make up a potential divider. The output voltage will be about half the supply voltage at a temperature around 25 °C. C7 and C8 suppress any possible interference. The NTCs (R9 and R10) are usually connected via several meters of cable, which can easily pick up interference. Both potential dividers are followed by a buffer stage (IC1a/IC1b). IC1c and R3, R4, R5 and R6 make up a differential amplifier (with unit gain), which measures the temperature difference (i.e. voltage difference).

When both temperatures are equal the output is 0 V. When the temperature of the solar collector rises, the differential amplifier outputs a positive voltage. This signal is used to trigger a comparator, which is built round an LM393 (IC2a). R7 and P1 are used to set the reference voltage at which the comparator changes state. R8 and P2 provide an adjustable hysteresis. R11 has been added to the output of IC2a because the opamp has an open collector output. A power switch for the pump is created by R12, T1 and Re1. D1 protects T1 against voltage spikes from the relay coil when it is turned off. A visual indication of the state of the controller is provided by IC4 (UAA170), a LED spot display driver with 16 LEDs. The reference voltage for the comparator is buffered by IC1d and fed to input VRMAX of the UAA170. R20/D21 and R23/D22 limit the input voltages of IC4 to 5.1 V, since the maximum permissible input voltage to the UAA170 is 6 V. When there is no temperature difference, LED D20 turns on.

Circuit diagram:

Temperature Sensitive Switch Circuit Diagram For Solar Collector

As the temperature difference increases the next LED turns on. The full scale of the LED bar is equal to the reference voltage of the comparator. This means that when the last LED (D5) of the UAA170 turns on, the comparator switches state. This is also indicated by D2. The power supply has been kept fairly simple and is built around a LM7812 regulator. The circuit is protected against a reverse polarity at the input by D3. You have to make sure that the input to the regulator is at least 15 V, otherwise it won’t function properly. There are a few points you should note regarding the mounting of the NTCs. NTC R9 should be placed near the output of the solar collector. You should choose a point that always contains water, even when some of the water flows back a little. NTC R10 should be mounted inside the filter compartment (where it exists), which continually pumps the swimming pool water.

This will give a good indication of the temperature of the water. The way the circuit has to be set up depends how it has been installed and is very much an experimental process. To start with, set hysteresis potentiometer (P2) halfway. Then set the reference voltage to about 1.5-2 V with P1. On a sunny day you can measure the voltage difference to get an idea as to which reference voltage needs to be adjusted. The hysteresis setting determines how long the pump stays on for, which is until the minimum temperature difference has been reached.

Author: Tom Henskens - Copyright: Elektor Electronics

Multitasking Pins Circuit Diagram

It’s entirely logical that low-cost miniature microcontrollers have fewer ‘legs’ than their bigger brothers and sisters – some-times too few. The author has given some consideration to how to economise on pins, making them do the work of several. It occurred that one could exploit the high-impedance feature of a tri-state output. In this way the signal produced by the high-impedance state could be used for example as a CS signal of two ICs or else as a RD/WR signal. All we need are two op-amps or comparators sharing a single operating voltage of 5 V and outputs capable of reaching full Low and High levels in 5-V operation (preferably types with rail-to-rail outputs).

Circuit diagram:

Multitasking Pins Circuit Diagram

Suitable examples to use are the LM393 or LM311. The resistances in the voltage dividers in this circuit are uniformly 10k. Consequently input A lies at half the operating voltage (2.5V), assuming nothing is connected to the input - or the microcontroller pin connected is at high impedance. The non-inverting input of IC1A lies at two-thirds and the inverting input of IC1B at one third of the operating voltage, so that in both cases the outputs are set at High state. If the microcontroller pin at input A becomes Low, the output of IC1B becomes Low and that of IC1A goes High. If A is High, everything is reversed.

Author : Roland Plisch - Copyright: Elektor Electronics 2008

Friday, September 27, 2013

Playback Amplifier For Cassette Deck

- Up to 50 Hz, corresponding to a time constant of 3.18 ms, the signal is highly and linearly amplified.

- Between 50 Hz and 1.326 kHz, corresponding to a time constant of 120 µs, for normal tape, or 2.274 kHz, corresponding to a time constant of 70 µs, for chromium dioxide tape, the signal is amplified at a steadily decreasing rate.

- Above 1.326 kHz or 2.274 kHz, as the case may be, the signal is slightly and linearly amplified. This characteristic is determined entirely by A1 (A1’). To make the amplifier suitable for use with chromium dioxide tape, add a double-pole switch (for stereo) to connect a 2.2 kΩ resistor in parallel with R3 (R3’). The output of A1 (A1’) is applied to a passive high-pass rumble filter, C3-R5 (C3’-R5’) with a very low cut-off frequency of 7 Hz. The components of this filter have exactly the same value as the input filter, C1-R1 (C1’-R1’). The second stage, A2 (A2’) amplifies the signal ´100, that is, to line level (1V r.m.s.).

Car Boot Lamp Warning ICM7556

After 5 seconds, the alarm will start to sound, and unless the lid is shut, it will continue for 1 minute to remind you to close the boot properly. The 1-minute operating period will ensure that the alarm does not sound continuously if you are, for example, transporting bulky items and the boot will not fully close. The circuit consists of a dual CMOS timer type 7556 (the bipolar 556 version is unsuitable for this application). When power is applied to the circuit (i.e. the boot lid is ajar) tantalum capacitors C1 and C2 will ensure that the outputs of the timers are high. After approximately 5 seconds, when the voltage across C2 rises to 2/3 of the supply voltage, timer IC1b will be triggered and its output will go low thereby causing the alarm to sound.

After 5 seconds, the alarm will start to sound, and unless the lid is shut, it will continue for 1 minute to remind you to close the boot properly. The 1-minute operating period will ensure that the alarm does not sound continuously if you are, for example, transporting bulky items and the boot will not fully close. The circuit consists of a dual CMOS timer type 7556 (the bipolar 556 version is unsuitable for this application). When power is applied to the circuit (i.e. the boot lid is ajar) tantalum capacitors C1 and C2 will ensure that the outputs of the timers are high. After approximately 5 seconds, when the voltage across C2 rises to 2/3 of the supply voltage, timer IC1b will be triggered and its output will go low thereby causing the alarm to sound.Meanwhile the voltage across C1 is rising much more slowly and after approximately 1 minute, it will have reached 2/3 of the supply voltage. IC1a will now trigger and this will reset IC1b. The alarm will be turned off. IC1a will remain in this state until the boot lid is either closed or opened wider at which point C1 and C2 will be discharged through R6 and the circuit will be ready to start again. To calculate the period of the timers use the formula: t = 1.1RC Please note that the capacitor type used in the circuit should be tantalum or electrolytic with a solid electrolyte. The buzzer must be a type suitable for use at D.C. (i.e. one with a built in driver).

One Transistor Radio

The sensitivity of this receiver is such that a 2 m length of wire is all that is needed as an antenna. The tap on the antenna coil is at 1/5th of the total winding on the ferrite rod. For details of the antenna coil see the article Diode Radio for Low Impedance Headphones. This circuit is suitable for reception of all AM transmissions from long-wave through to shortwave.

The sensitivity of this receiver is such that a 2 m length of wire is all that is needed as an antenna. The tap on the antenna coil is at 1/5th of the total winding on the ferrite rod. For details of the antenna coil see the article Diode Radio for Low Impedance Headphones. This circuit is suitable for reception of all AM transmissions from long-wave through to shortwave.Thursday, September 26, 2013

Push Off Push On

The ubiquitous 555 has yet another airing with this bistable using a simple push-button to provide a push-on, push-off action. It uses the same principle of the stored charge in a capacitor taking a Schmitt trigger through its dead-band. Whereas the Schmitt trigger in that reference was made from discrete components, the in-built dead-band arising from the two comparators, resistor chain and bistable within the 555 is used instead. The circuit demonstrates a stand-by switch, the state of which is indicated by illumination of either an orange or red LED, exclusively driven by the bipolar output of pin 3. Open-collector output (pin 7) pulls-in a 100-mA relay to drive the application circuit; obviously if an ON status LED is provided elsewhere, then the relay, two LEDs and two resistors can be omitted, with pin 3 being used to drive the application circuit, either directly or via a transistor.

Circuit diagram:

Push Off Push On Circuit Diagram

The original NE555 (non-CMOS) can source or sink 200 mA from / into pin 3. Component values are not critical; the ‘dead-band’ at input pins 2 and 6 is between 1/3 and 2/3 of the supply voltage. When the pushbutton is open-circuit, the input is clamped within this zone (at half the supply voltage) by two equal-value resistors, Rb. To prevent the circuit powering-up into an unknown condition, a power-up reset may be applied with a resistor from supply to pin 4 and capacitor to ground. A capacitor and high-value resistor (Rt) provide a memory of the output state just prior to pushing the button and creates a dead time, during which button contact bounce will not cause any further change. When the button is pressed, the stored charge is sufficient to flip the output to the opposite state before the charge is dissipated and clamped back into the neutral zone by resistors Rb. A minimum of 0.1 µF will work, but it is safer to allow for button contact-bounce or hand tremble; 10 µF with 220 k gives approximately a 2-second response.

Author: Trevor Skeggs - Copyright: Elektor July-August 2004

Source : www.extremecircuits.net

Low Cost 2x20 Watt Stereo Amplifier by TDA2005

You should use thermal paste to improve the heat dissipation. After the assembly , case construction is left to the builder. 100K potentiometers are used for adjusting the input volume. The potentiometers are absent in the layout. The 100K resistors need only be installed if the 100 K potentiometers are not used as shown in the layout. You should use a well designed quality transformer to get less noise. It will be another good way to use a sufficient battery to power the circuit. Keep the supply wires as short as possible. Input source should be isolated from the external noises too. It is recommended to use coaxial cable to connect the input audio.

You should use thermal paste to improve the heat dissipation. After the assembly , case construction is left to the builder. 100K potentiometers are used for adjusting the input volume. The potentiometers are absent in the layout. The 100K resistors need only be installed if the 100 K potentiometers are not used as shown in the layout. You should use a well designed quality transformer to get less noise. It will be another good way to use a sufficient battery to power the circuit. Keep the supply wires as short as possible. Input source should be isolated from the external noises too. It is recommended to use coaxial cable to connect the input audio.

Technical data:

Technical data:Performance of TDA2005M: (for this circuit); At 14.4 V supply voltage: 2 x 20 watts (stereo) into 4 Ohms.

Distortion: Approx. 0.2% at 4 Watts into 4 ohm load.

Frequency Range: Approx. 20 Hz to 22 KHz.

Input Sensitivity: Approx. maximum 150 mV rms. .

Power supply: + 8 to 18 volts, approx. maximum 3.5 Amps per channel.

Home Network for ADSL

- orange/white

- orange

- green/white

- blue

- blue/white

- green

- brown/white

- brown

Wednesday, September 25, 2013

Experimental Pendulum Clock

Below the rod and 15mm to the left is the impulse solenoid, with a core but no actuator attached. The circuit comprises of four parts: (1) the sensor; (2) the counter and solenoid driver; (3) the clock driver; and (4) the clock. The sensor is built on its own small piece of strip board and is located on the centre line of the backboard behind the reflector. It utilises a Sharp IS471F infrared modulated detector (Farnell cat. 414-2860) to eliminate interference from external light sources. The infrared emitter (IRLED1) must be mounted near to the detector (IRDET1) but be masked from it.

The emitter radiates a coded signal toward the reflector. As the pendulum passes the centre line it reflects the signal back to the detector, which then gives a negative-going output pulse on pin 2. This makes the surface-mount LED (LED1) flash once. It also sends a signal to the counter and clock driver circuits on the main circuit board. Pulses from the sensor are fed into IC1, a 4020 14-stage ripple counter. The counter’s output (pin 6) goes high every 128 counts (seconds). These long duration pulses are inverted by transistor Q1 and differentiated by the 10nF capacitor and 22kO resistor, providing a narrow trigger pulse for a 7555 CMOS timer (IC2).

The 7555 is wired as a monostable, driving the base of transistor Q3 with a relatively short pulse width suitable for energising the impulse solenoid. LED2 flashes in unison with solenoid pulses, and can be mounted right on the solenoid as a visual aid. Pushbutton switch S2 is used to provide gentle starting pulses to get the pendulum swinging smoothly at the outset. Switch S1 resets the counter to zero. With this arrangement, the pendulum is set swinging and when it is to the left of centre, S1is pushed. Thus, the pendulum moves right to left on even numbered counts. At the 128th count, the solenoid gives a shot pull to the left just as the pendulum is passing through the centre line and moving right to left.

The distance of the solenoid below the pendulum is adjusted so that it does not jerk the pendulum but adds a gentle nudge. The clock driver circuit also derives its timing from the output of the sensor. Negative-going pulses from the sensor are inverted by Q4 before being fed into a 4013 flipflop. On the output side, pins 12 & 13 go high in turn for one second. These pulses are too long to directly drive the clock coil, so they’re logically "anded" with the short pulses from the sensor using two gates of a 4093 NAND Schmitt trigger (IC4). The outputs from these gates then drive an adapted quartz clock movement.

A suitable clock can be made from a standard quartz movement by isolating the coil and removing the battery. See SILICON CHIP, Dec. 1996, page 38 for full instructions or October 2001 page 37 for brief notes. This is an experimental clock so you may have to try various solenoids to find one that works for you. If necessary, the solenoid pulse duration can be changed by varying IC2’s timing components. If the suspension is too stiff, try impulsing at 64 beats from pin 4 of IC1, but note that the aim is to get the freest pendulum movement possible. The Synchronome and Hipp clocks were impulsed at 30-second intervals, so your clock could be even better.

In the prototype, the reflector was made from the back of an adhesive cable clip snapped on to the pendulum rod. The white back was masked to give a 5mm wide central vertical strip, giving clean, short pulses as the pendulum passes. Current drain is several milliamps, so the prototype was powered from an SLA battery fed from a float charger. A pendulum beating in seconds is called a Royal pendulum. Its length is the same as one in a typical long case (grandfather) clock.

Reset Sequencer Circuit

It is often necessary in complex designs to provide a sequence of reset pulses to different parts of a circuit to ensure the whole design functions reliably. The DS1830 from Maxim (www.maxim-ic.com) provides three sequenced open-drain reset outputs. This chip is designed for 5 V systems but a 3.3 V version (DS1830A) is also available. Both are offered in a range of package outlines including DIP, SO and µSOP. Two inputs give the chip some degree of programmability of its characteristics: The TOL input defines the chips tolerance to power supply fluctuations before a reset sequence is triggered.

Circuit diagram:

Reset Sequencer Circuit Diagram

| TOL | 5V | 3,3 V | TD | Tr1 | Tr2 | Tr3 |

| + Ub | Ub .0.95 | Ub .0.95 | 0 V | 10 ms | 50 ms | 100 ms |

| 0 V | Ub .0.90 | Ub .0.90 | Open | 20 ms | 100 ms | 200 ms |

| Open | Ub .0.85 | Ub .0.80 | + Ub | 50 ms | 250 ms | 500 ms |

Jumper JP1 allows the TOL to be connected to Ub (Vcc), ground or left open circuit and will result in the following three reset thresholds: The TD input allows the length of the reset signal to be programmed and jumper JP2 gives the following three possibilities: The PBRST (pushbutton reset) allows a manual reset button to be connected to the chip. This input has a built-in 40 k? pull up resistor and can also be driven by a digital output or used to cascade additional devices to provide more sequenced reset signals.

Author: Gregor Kleine Copyright: Elektor Electronics

Simple Combination Lock Circuit

This simple combination lock accommodates codes from 1-9 digits long, with the only restriction being that the same digit cannot be used twice. The circuit shows strapping for a 4-digit code, in this case "2057". Any unused switches are strapped to ground. When power is applied, the 330nF capacitor connected to pin 1 of inverter IC1a is discharged, holding it at a logic low level. The high output is inverted by a second gate (IC1b), with the result being a logic low on pin 4. This pulls Q1’s emitter low via D1, causing the transistor to conduct. The falling voltage on the collector then pulls the input of IC1c low, which in turn resets counter IC2.

On reset, output O0 (pin 3) of IC2 goes high, charging the 330nF capacitor via D2 and the 33kΩ resistor. If switch S2 is now pressed, Q2s emitter will be pulled high and so Q2 conducts, applying a rising positive voltage to one end of the 1MΩ resistor. This resistor and the 33nF capacitor act as a switch "debounce" circuit, delaying the pulse through IC1e by about 33ms. After the delay, the output of IC1e goes low. However, counter IC2 does not increment at this stage, since it needs a positive-going edge at the clock input (pin 14). When the switch is released, Q2 turns off, IC1e’s output goes high after the debounce period and the counter advances to the next state (ie. O0 goes low and O1 goes high).

Circuit diagram:

Simple Combination Lock Circuit Diagram

When output O0 (pin 3) goes low, the 330nF capacitor starts discharging through the 33kΩ and 10MΩ resistors. This allows about 3s for the operator to press the next button. If no button is pressed within this period, IC1b’s output goes low, which pulls Q1’s emitter low and resets the counter via IC1c. Hence the code entry must be restarted. When the second digit of the code is entered (0 in this example), Q2’s emitter is again pulled high. Q2 thus turns on and after the debounce delay, IC1e’s output goes low. When the switch is released, Q2 turns off, IC1e’s output goes high and the counter advances to state 2.

Note that while the switch is pressed, IC1d’s output is high, recharging the 330nF capacitor and therefore resetting the 3s delay. Thus, the operator is allowed another 3s to press the next digit. This process is repeated for each digit in the sequence. If the wrong switch is pressed at any point, IC2 is reset as described above. Conversely, if the correct code is entered, IC1 advances to state 4 (for our 4-digit example) on release of the fourth switch. Output O4 then goes high and turns on Q3 and relay 1. Q3 can handle up to about 300mA of load current. If more current is required, then either a Darlington or power Mosfet can be substituted. D4 is required if the load is inductive (eg, a relay, solenoid, etc).

Author: Len Cox - Copyright: Silicon Chip Electronics

Tuesday, September 24, 2013

Battery Charger for vehicles

We hope this circuit will help you to understand the action of a Battery charger. Lot of people has no idea how simple it is. In this circuit we have used two diodes, one capacitor and a transformer. Ammeter is not necessary but it helps us to determine the charging level of the battery.

When you finish the circuit just connect the positive and negative wires to the battery terminals. Make sure to connect the positive wire to the positive terminal of the battery. When the charging is going on you can see 1 to three amps in the ammeter but when the charge is finish or the circuit is disconnected the reading should be zero.

We have used two diodes for full wave rectification and a capacitor is used for DC smoothing. Capacitor is not necessary but we recommend you to use the capacitor always.

The charging time will depend on the size of the transformer, means if we connect a big transformer that means battery gets a higher current ( more than 5A ). Incase if you want to use a higher current transformer use big diodes to pass the current accordingly.

LED Light Pen

The constant current through the white LED is calculated from R2 = 0.65 / I LED With some skill the complete circuit can be built such that its size is equal to an AA battery. The four button cells take the place of the other AA battery that used to be inside the light pen.

Traffic Lights For Model Cars Or Model Railways

This gives about 6 seconds for the red and green LEDs and 3 seconds for the orange. When power is first applied, the RC network connected to pins 1 and 15 of IC2 resets the 4017 and the green LED cycle begins. The orange and red cycles follow and at the end of the red cycle, pin 1 will go high to reset the 4017 to start the green cycle all over again. You can experiment with the cycle times by adjusting the 220kO resistor or by combining more or less 4017 outputs to achieve different ON times for the three LEDs.

The circuit is designed to be powered by a 9V battery and this is the maximum voltage that is recommended. This is because the LEDs are directly driven by the 4017 with no current limiting resistor being used. The 4017 naturally limits the current that it can supply to 15mA. An extension of this project would be to make a second set of lights for the cross traffic. Here you would use the same 555 as a master timer for both sets of lights (otherwise chaos would ensue) and a separate 4017 to drive the three extra LEDs. Of course, you would have to take care and ensure that green and orange outputs on each set of lights correspond with red on the other!

Monday, September 23, 2013

Electronic Motor Starter

Switch S1 is used to turn on the pump, while switch S2 is used to turn off the pump. While making over-/under-voltage setting, disconnect C2 temporarily. Capacitor C2 prevents relay chattering due to rapid voltage fluctuations. Regulator IC 7809 gives the 9V regulated supply to soft switch as well as the relay after filtering by capacitor C4. A suitable miniature circuit breaker is used for automatic over-current protection. Green LED (LED1) indicates that the motor is ‘on’ and red LED (LED2) indicates that the power is ‘on’. The motor is connected to the normally-open contact of the relay. When the relay energizes, the motor turns on.

Switch S1 is used to turn on the pump, while switch S2 is used to turn off the pump. While making over-/under-voltage setting, disconnect C2 temporarily. Capacitor C2 prevents relay chattering due to rapid voltage fluctuations. Regulator IC 7809 gives the 9V regulated supply to soft switch as well as the relay after filtering by capacitor C4. A suitable miniature circuit breaker is used for automatic over-current protection. Green LED (LED1) indicates that the motor is ‘on’ and red LED (LED2) indicates that the power is ‘on’. The motor is connected to the normally-open contact of the relay. When the relay energizes, the motor turns on.Reflector For Pedestrians

Fit a 6 V bulb in a suitable holder in the 10 mm hole. Fit a suitable clip and, optionally an on/off switch, at the rear of the enclosure. See Figure 1. The electronic circuit consists of a light-sensitive switch, composed of P1, a photo-conductive cell, LDR, and IC1a; an inverter, IC1b;, an oscillator, IC1c with R1 and C1; a buffer, IC1d with R2 and T1; and a 6–9 V bulb that draws a current of not more than 50mA. The photo-conductive cell (or light-sensitive resistor) should be exposed to ambient light, but not to the light bulb, of course. Its sensitivity is set with P1.

Fit a 6 V bulb in a suitable holder in the 10 mm hole. Fit a suitable clip and, optionally an on/off switch, at the rear of the enclosure. See Figure 1. The electronic circuit consists of a light-sensitive switch, composed of P1, a photo-conductive cell, LDR, and IC1a; an inverter, IC1b;, an oscillator, IC1c with R1 and C1; a buffer, IC1d with R2 and T1; and a 6–9 V bulb that draws a current of not more than 50mA. The photo-conductive cell (or light-sensitive resistor) should be exposed to ambient light, but not to the light bulb, of course. Its sensitivity is set with P1.1988 Chevrolet chevy c1500 Wiring Diagram

|

| 1988 Chevrolet chevy c1500 Wiring Diagram |

adaptor, programming clip, power input, blue wire, speedometer, see ground, gasoline, diesel vin, magnet generator, cruise control module, odometer, speedometer, rear wheel anti lock brake module, ground distribution, input buffer, connector.

Infrared Proximity Detector Alarm

The choice of the two infrared components used in this circuit will be uncritical but they must be ‘band’ compatible, i.e., generate (D1) and respond to (D2) the same wavelength. The operating point of the receiver input circuit is rather dependent on ambient day-light levels and the value of R4 may need to be adjusted a little to ensure a voltage of between 1.5 V and 4 V on the collector of T1 when no signal is being received. Some dc buzzers cause a lot of back-emf so it may be necessary to insert a diode in series with the output of IC1. If necessary, this diode should preferably be a Schottky type because of the inherent low voltage drop of about 0.4 V as opposed to 0.65 V for a typical small-signal silicon diode.

Sunday, September 22, 2013

Fan Controller Using Just Two Components

HYST = Hysteresis

open = 1 °C

ground = 4 °C

+3.3V = 8 °C

DC DC Converter From 1 5V To 34V

If the voltage sampled at the feedback input drops below the reference threshold level of 1.23 V, the transistor switches on and the current in the coil starts to increase. This builds up energy in the magnetic field of the coil. When the current through the coil reaches 350 mA, the monostable is triggered and switches the transistor off for the following 400 ns. Since the energy stored in the coil must go somewhere, current continues to flow through the coil, but it decreases linearly. This current charges the output capacitor via the Schottky diode (SS24, 40V/2A). As long as the voltage at FB remains higher than 1.23V, nothing else happens.

As soon as it drops below this level, however, the whole cycle is repeated. The hysteresis at the FB input is 8mV. The output voltage can be calculated using the formula Vout = 1.23V (R1+R2) / R2 The value of R1 can be selected in the megohm range, since the current into the FB input is only a few tens of nano-amperes. When the supply voltage is switched on, or if the output is short-circuited, the IC enters the power-up mode. As long as the voltage at FB is less than 0.6V, the LT1615 output current is limited to 250mA instead of 350mA, and the monostable time is increased to 1.5µs.

As soon as it drops below this level, however, the whole cycle is repeated. The hysteresis at the FB input is 8mV. The output voltage can be calculated using the formula Vout = 1.23V (R1+R2) / R2 The value of R1 can be selected in the megohm range, since the current into the FB input is only a few tens of nano-amperes. When the supply voltage is switched on, or if the output is short-circuited, the IC enters the power-up mode. As long as the voltage at FB is less than 0.6V, the LT1615 output current is limited to 250mA instead of 350mA, and the monostable time is increased to 1.5µs.These measures reduce the power dissipation in the coil and diode while the output voltage is rising. In order to minimize the noise voltages produced when the coil is switched, the IC must be properly decoupled by capacitors at the input and output. The series resistance of these capacitors should be as low as possible, so that they can short noise voltages to earth. They should be located as close to the IC as possible, and connected directly to the earth plane. The area of the track at the switch output (SW) should be as small as possible. Connecting a 4.7-µF capacitor across the upper feedback capacitor helps to reduce the level of the output ripple voltage.

The selection of the coil inductance is described in detail in the LT1615 data sheet at www.linear-tech.com. Normally, a 4.7µH filter choke is satisfactory for output voltages less than 7V. For higher voltages, a 10-µH choke should be used. In the data sheet, the Coilcraft DO1608-472 (4.7 µF) and DO1608-100 (10 µF) are recommended. The Schottky diode must naturally have a reverse blocking voltage that is significantly greater than the value of the output voltage. The types MBR0530 and SS24 are recommended. The shutdown input (/SHDN) can be used to disable the step-up regulator by applying a voltage that is less than +0.25V.

The selection of the coil inductance is described in detail in the LT1615 data sheet at www.linear-tech.com. Normally, a 4.7µH filter choke is satisfactory for output voltages less than 7V. For higher voltages, a 10-µH choke should be used. In the data sheet, the Coilcraft DO1608-472 (4.7 µF) and DO1608-100 (10 µF) are recommended. The Schottky diode must naturally have a reverse blocking voltage that is significantly greater than the value of the output voltage. The types MBR0530 and SS24 are recommended. The shutdown input (/SHDN) can be used to disable the step-up regulator by applying a voltage that is less than +0.25V.If the voltage at this pin is +0.9 V or higher, the LT1615 is active. You must bear in mind that even when the IC is disabled, the input voltage still can reach the output via the coil and the diode, reduced only by the forward voltage drop of the diode. The second circuit diagram for the LT1615 (Figure 2) shows how you can make a symmetric power supply using this switching regulator. Here the switch output of the IC is tapped off and rectified using a symmetrical rectifier. The voltage divider at the positive output of the rectifier determines the output voltage.

Hybrid Headphone Amplifier

Potentially, headphone listening can be technically superior since room reflections are eliminated and the intimate contact between transducer and ear mean that only tiny amounts of power are required. The small power requirement means that transducers can be operated at a small fraction of their full excursion capabilities thus reducing THD and other non-linear distortions. This design of a dedicated headphones amplifier is potentially controversial in that it has unity voltage gain and employs valves and transistors in the same design. Normal headphones have an impedance of 32R per channel. The usual standard line output of 775 mV to which all quality equipment aspires will generate a power of U2 / R = 0.7752 / 32 = 18 mW per channel across a headphone of this impedance.

An examination of available headphones at well known high street emporiums revealed that the sensitivity varied from 96 dB to 103db/mW! So, in practice the circuit will only require unity gain to reach deafening levels. As a unity gain design is required it is quite possible to employ a low distortion output stage. The obvious choice is an emitter follower. This has nearly unity gain combined with a large amount of local feedback. Unfortunately the output impedance of an emitter follower is dependent upon the source impedance. With a volume control, or even with different signal sources this will vary and could produce small but audible changes in sound quality.

To prevent this, the output stage is driven by a cathode follower,based around an ECC82 valve (US equivalent: 12AU7).

This device, as opposed to a transistor configuration, enables the output stage to be driven with a constant value, low impedance. In other words, the signal from the low impedance point is used to drive the high impedance of the output stage, a situation which promotes low overall THD. At the modest output powers required of the circuit, the only sensible choice is a Class A circuit. In this case the much vaunted single-ended output stage is employed and that comprises of T3 and constant current source T1-T2.

Circuit diagram:

Hybrid Headphone Amplifier Circuit Diagram

The constant current is set by the Vbe voltage of T1 applied across R5 With its value of 22R, the current is set at 27 mA. T3 is used in the emitter follower mode with high input impedance and low output impedance. Indeed the main problem of using a valve at low voltages is that it’s fairly difficult to get any real current drain. In order to prevent distortion the output stage shouldn’t be allowed to load the valve. This is down to the choice of output device. A BC517 is used for T3 because of its high current gain, 30,000 at 2 mA! Since we have a low impedance output stage, the load may be capacitively coupled via C4. Some purists may baulk at the idea of using an electrolytic for this job but he fact remains that distortion generated by capacitive coupling is at least two orders of magnitude lower than transformer coupling.

The rest of the circuitry is used to condition the various voltages used by the circuit. In order to obtain a linear output the valve grid needs to be biased at half the supply voltage. This is the function of the voltage divider R4 and R2. Input signals are coupled into the circuit via C1 and R1. R1, connected between the voltage divider and V1’s grid defines the input impedance of the circuit. C1 has sufficiently large a value to ensure response down to 2 Hz. Although the circuit does a good job of rejecting line noise on its own due to the high impedance of V1’s anode and T3’s collector current, it needs a little help to obtain a silent background in the absence of signal.

The ‘help’ is in the form of the capacitance multiplier circuit built around T5. Another BC517 is used here to avoid loading of the filter comprising R7 and C5. In principle the capacitance of C5 is multiplied by the gain of T5. In practice the smooth dc applied to T5’s base appears at low impedance at its emitter. An important added advantage is that the supply voltage is applied slowly on powering up. This is of course due to the time taken to fully charge C5 via R7. No trace of hum or ripple can be seen here on the ‘scope. C2 is used to ensure stability at RF. The DC supply is also used to run the valve heater. The ECC82 has an advantage here in that its heater can be connected for operate from 12.6 V. To run it T4 is used as a series pass element. Base voltage is obtained from the emitter of T5. T4 has very low output impedance, about 160 mR and this helps to prevent extraneous signals being picked up from the heater wiring. Connecting the transistor base to C5 also lets the valve heater warm up gently. A couple of volts only are lost across T4 and although the device runs warm it doesn’t require a heat-sink.

Author: Jeff Macaulay - Copyright: Elektor Electronics

Saturday, September 21, 2013

Battery Charger Display Using LT1639

The current source formed by IC1a and T1 is active when the batteries are discharging and IC1b and T2 is active when the batteries are being charged. In each case the inactive opamp will have 0V at its output and the corresponding transistor will be switched off. IC1d amplifies the voltage across R5, which is proportional to the sense current. The component values given in the diagram produce an amplification factor or 10. A sense current of 0.1 A will produce an output voltage of +1 V. The supply voltage to the circuit is +5 V so this will be the maximum value that the output can achieve. This corresponds to a maximum charge/discharge current of 0.5 A To display currents from 0 to 5.0 A, resistor R7 can be omitted to give IC1d a voltage gain of 1.

The current source formed by IC1a and T1 is active when the batteries are discharging and IC1b and T2 is active when the batteries are being charged. In each case the inactive opamp will have 0V at its output and the corresponding transistor will be switched off. IC1d amplifies the voltage across R5, which is proportional to the sense current. The component values given in the diagram produce an amplification factor or 10. A sense current of 0.1 A will produce an output voltage of +1 V. The supply voltage to the circuit is +5 V so this will be the maximum value that the output can achieve. This corresponds to a maximum charge/discharge current of 0.5 A To display currents from 0 to 5.0 A, resistor R7 can be omitted to give IC1d a voltage gain of 1.Higher currents can be displayed by using a lower value of sense resistor R8. A DVM or analogue meter can be used at Vout to give a display of the charge/discharge current. The constant current sources can only function correctly when the supply to the voltage regulator circuit (UBatt. e.g. 6V or 12V) is greater than the operating voltage of the opamps (+5 V). The supply voltage to the LT1639 can be in the range of +3 V and +44V and voltages up to 40V over the supply voltage are acceptable at the inputs to the opamp. IC1c controls the charging/discharging LED output. The inputs to this opamp are connected to the outputs of the current source opamps and its output goes high when the battery is being charged and low when it is discharging.

Voltage Levels Control Relays

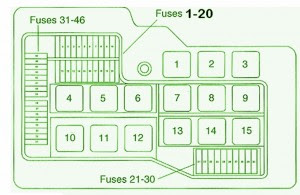

Fuse Box BMW 325i 1994 Diagram

Fuse Box BMW 325i 1994 Diagram

Fuse Panel Layout Diagram Parts: ABS system, ABS pump, high speed radiator, A/C compressor, low speed radiator, horn relay, taillight/foglight relay, fuel pump relay, system main relay, oxygen sensor heater, rear defogger, low beam relay, high beam relay.

Fuse Box BMW 745 2005 Diagram

Fuse Box BMW 745 2005 Diagram

2005 BMW 745 Fuse Box Diagram: damper control, engine control gasoline, heated steering wheel, ignition starter switch, independent heater, adaptive head light, ABS, auxiliary heater diesel, blower, wiper/washer systemdiagnosis plug, burning heater, deflation warning system, door window lift, central locking system, LK doors, central locking system, remote control, cigar lighter, Radio, rear screen, roller sun blind, seat adjustment, seat heating, servotronic, speed control, starter diesel engine, steering column adjustment, CD changer, transmission control, instrument cluster, lighting, multi function steering, wheel, on board monitor, parking brake, airbag, air conditioner, anti roll stabilize.

Friday, September 20, 2013

2009 BMW Z4 Wiring Diagram

|

| 2009 BMW Z4 Wiring Diagram |

neutral gear switch, hego ground, power ground, exhaust gas oxygen sensor, engine coolant temperature sensor, throttle position, air charger temperature, barometric pressure sensor, EGR valve position sensor, mass air flow sensor, power relay, battery, WAC relay, A/C clutch, pressure switch.